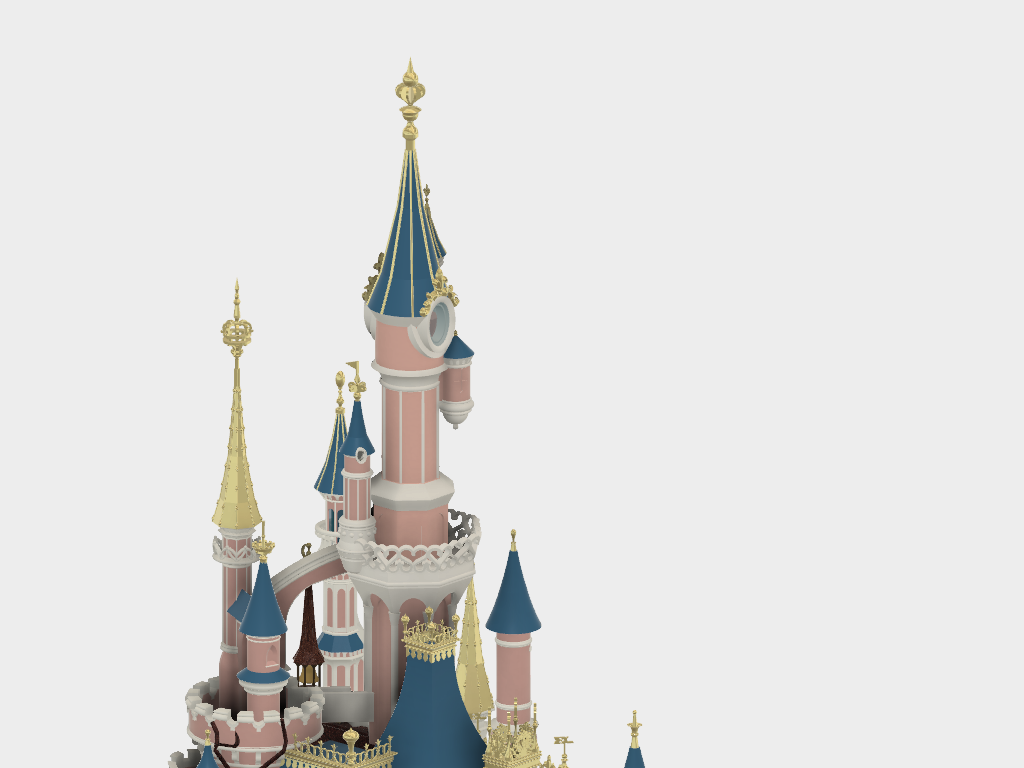

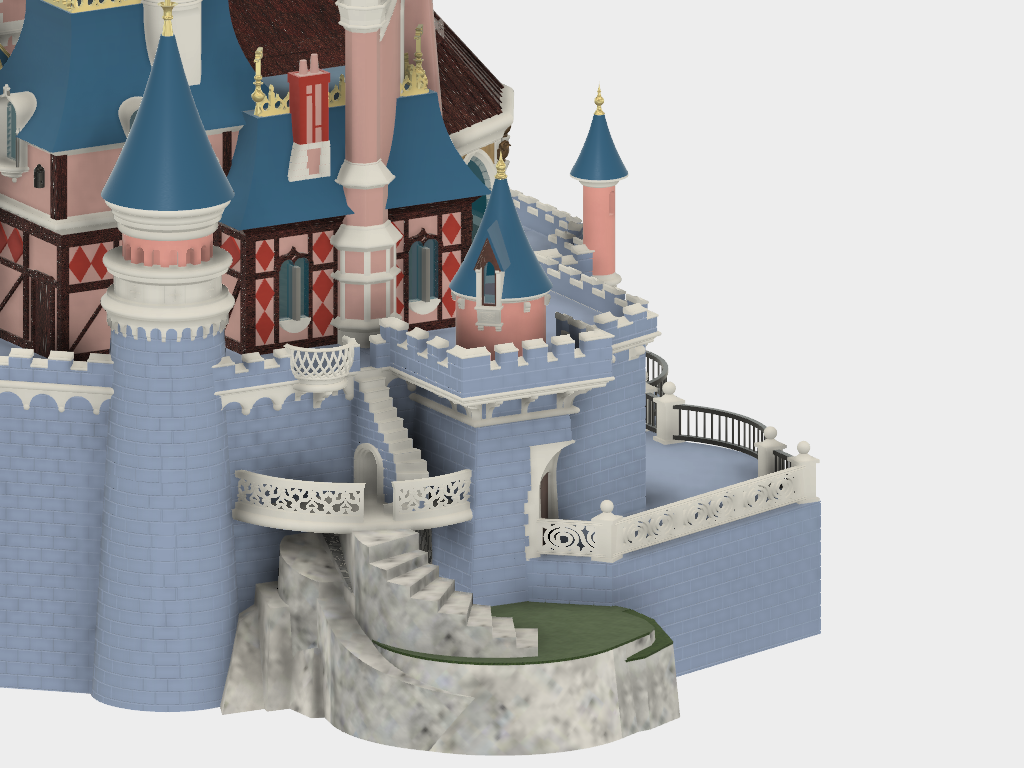

Passionate about chateau and Disney, I undertook to make a model of Disneyland Paris' Château de la Belle au Bois Dormant. The first difficulty in modeling the castle was to find sufficiently detailed plans, as the many photos taken on site did not allow the building, which is very complicated, to be accurately reconstructed.

After a lot of research I came across Robert Nava's extraordinary paper model on his website https://www.disneyexperience.com/models/dlpcastle

I therefore reused these plans to model the entire castle, enriching the paper model with architectural details taken in photos on site and not reproducible on paper.

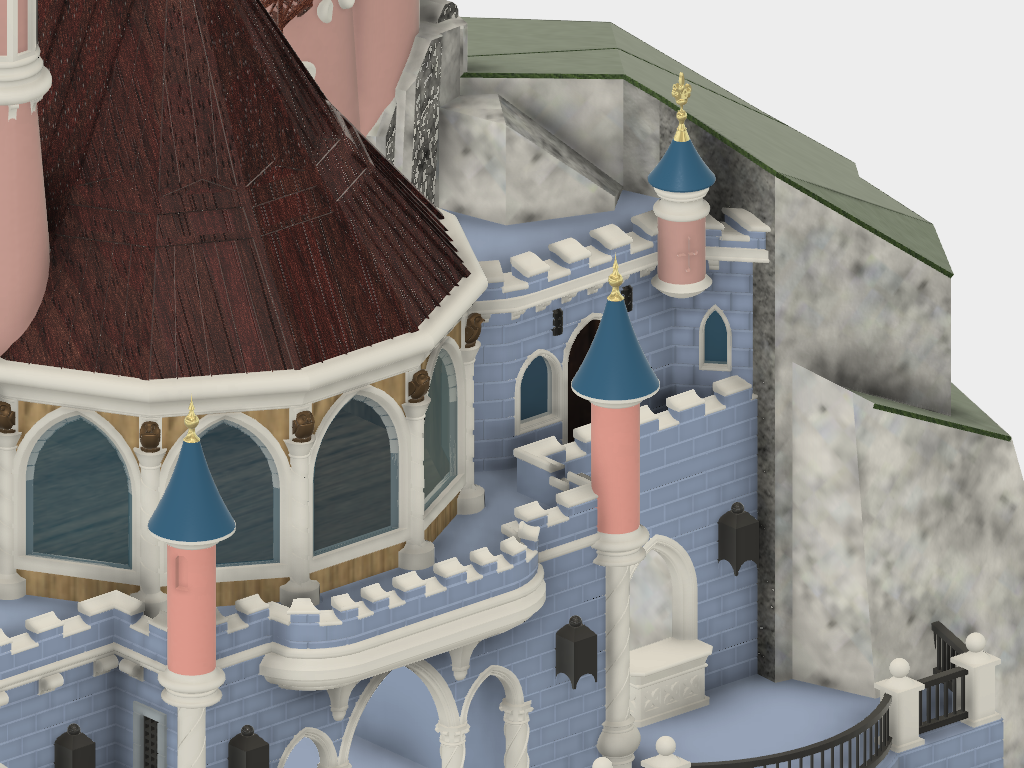

A few hundred hours were necessary for the modeling, which was done under Fusion 360 but much more for the printing! With a Prusa MK2S printer with the 4-colour Multimatéraux option, the modeling was done in such a way as to print the parts directly in the desired colours, which minimizes or even eliminates the need for a paint finish.

The colours used are those closest to the original, pink, white, glitter blue, gold, red, green, light and dark brown, light and dark grey.

The assembly manual I put in the files is the one of the paper model. It does not apply of course but will help you in the assembly because I kept the same letter references as in Robert Nava's model, the assembly is quite delicate because of the interlocking of the parts, and it will be necessary from time to time to use the cutter or file to adjust the parts. There is indeed no play between the different parts in the modeling.

It is in conclusion a very big job, but the result rewards the past hours, as you can see on the pictures of the model in its current state, because it is not yet finished (the first 15 pictures). I also added screenshots of the modeling.

It should be noted that I have taken over the drawings from the paper model for the finishing of the doors and stained glass windows, which have been printed in translucent sheets to allow the castle to be illuminated.

Good realization to those who will embark on the adventure, I will answer as much as possible the questions or difficulties that you may encounter. Please do not hesitate to make any comments. Be careful the.zip file is 124 Mb.

It is of course forbidden to resell in any form whatsoever files or prints from this project (the original plans are free and Disney jealously watches over its copyright!!!), but you can share it as you wish, without however modifying it.

I would like to thank Robert Nava again for his exceptional modeling work, without which I would not have been able to complete this project.

Edition 2 OF NOVEMBER 1, 2018

The files in the "Access ramp" folder have been redrawn to make them easier to print.